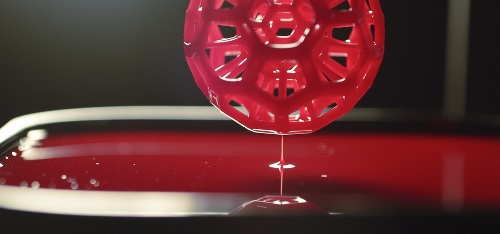

CLIP technology in action.

For those that still think of 3D printing as nothing more than a novel curiosity, it’s time to take another look. Recent innovations and triumphs, including entire apartments being printed and printers being built for chemical synthesis, have done much to overturn a stubborn notion that 3D printers are nothing more than a passing fad. 3D printed firearms have already been manufactured, leading to hot debates about security and law revision. At this point in time, it is perhaps wise to discuss not if 3D printing will become a substantial part of our future world, but rather the implications it has for the global economy and security.

Rise of the machines

3D printing, also known as additive manufacturing (AM), works by using a computer to print layers of materials consisting of plastic resin or even metal on top of one another to create a finished product. Adopted in the 1980s, AM technology was originally expensive and used mainly for visualization and laser work. Even in 2011, an average printer could still cost as much as $20,000. These days, a machine can cost less than 1% of that. A PWC survey in 2013 recently showed than 66 out of 100 industrial manufacturers are using AM, mainly for prototyping.

This is just the tip of the iceberg. A new advancement in AM technology by Carbon3D has the potential to overhaul the industry again. Inspired by Terminator villain T-1000, they claim their continuous liquid interface production (CLIP) technology can print 25 to 100 times faster than existing printers, and at a much higher quality. Available as soon as next year, CLIP overhauls the notion that 3D printers are unsuitable for larger volumes of manufacturing, and has large implications for global manufacturing.

Outsourcing will be out

The immediate inferences that we can make are twofold. First, a commercialized manufacturing technology that doesn’t require much labor or imported materials deals a huge blow to outsourcing. If CLIP or a similar technology becomes commercialized enough so that printers and materials are readily available to everyone, economies of scale based on cheap labour will decline. The point of production of printed goods will become so close to the point of consumption that transportation costs for imported goods will be magnified in comparison. Short of inventing a space-time portal, no cut of labour costs will offset the price of shipping across an ocean. China and Southeast Asian countries have used the mass manufacturing model as a catalyst for their economic growth for the past few decades, and an exodus of foreign demand threatens to halt their development. Obviously, many products do not lend themselves to 3D printing and the Asian countries have plenty of local demand, but the gradual flow of wealth and capital to the East may slow down to a trickle.

The second implication is the decline of brands. With endless customization options available with just tweaks in the code of product designs, amateur and small-scale artisans and designers can become much more competitive. Just as a whole generation of YouTube producers challenged traditional media companies, anyone can pit their designs against industry giants. The playing field would be largely evened thanks to the Internet, and the high prices that big brands pay for design may have to be re-evaluated.

Unknown territory ahead

Components of a 3D printed gun.

However, 3D printing also brings with it security concerns. Intellectual property (IP) theft is a prime issue, with some research predicting that 3D printing will cost US $100 billion in losses annually by 2018 due to IP related issues. There is no precedence for many of the patent laws and infringements that will no doubt follow the widespread use of AM.

Furthermore, with technology that bypasses so much of the manufacturing chain, jobs may be lost in droves in economies that have not become totally service-oriented. Civil unrest may arise in tandem with this unemployment, which exacerbates the problem that 3D printed weapons cannot be as rigidly controlled through traditional means such as licences.

Rapid advancements in AM technology have been unleashed upon the world in the past few years and see few signs of stopping. Though industry leader MakerBot has recently suffered setbacks, it appears to only be a matter of time before 3D printing becomes completely mainstream. The world has been set on a technological thrill ride and only time will tell how it will end.